-

Welcome, Guest

- ( My Account | View Cart | Login )

ARTISAN MADE

OTHER PRODUCTS

KNIFEMAKING SUPPLIES

STAFF PICKS & GIFT IDEAS

SERVICES

INFORMATION

Featured Products

Three Books by Dr. David Darom: Art and Design in Modern Custom Fixed-Blade Knives, Art and Design in Modern Custom Folding Knives, and The Art of Custom Knifemaking

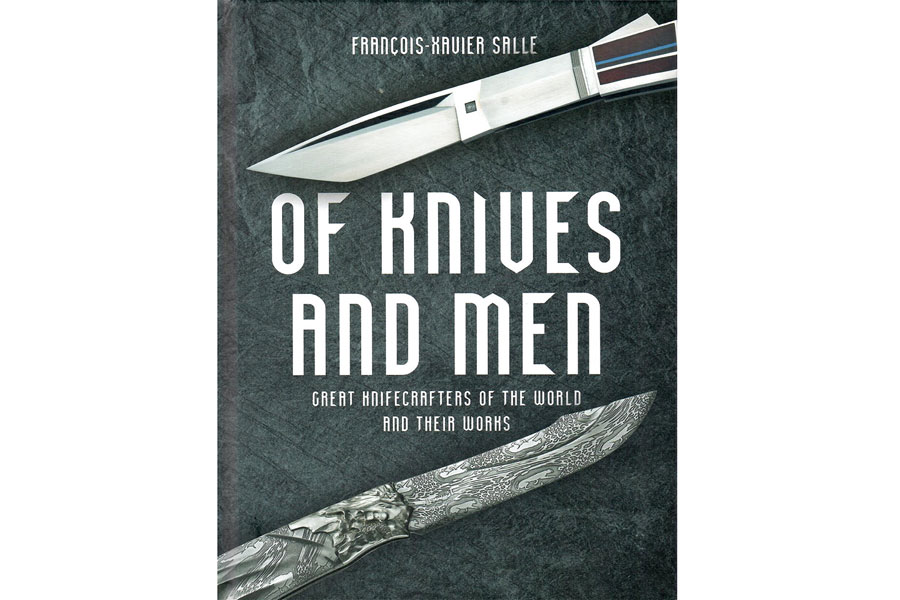

Of Knives And Men - Great Knifecrafters Of The World And Their Works by Francois-Xavier Salle

Orca 2.0 Frame Lock Flipper with African Blackwood Inlay - Stonewash M390 - Serial 108

Orca 2.0 Frame Lock Flipper with Red Mammoth Molar Inlay - Stonewash M390 - Serial 088

Orca 2.0 Frame Lock Flipper with Gold Snakeskin FatCarbon Inlay - Stonewash M390 - Serial 129

Orca 2.0 Frame Lock Flipper with Green TechnoCarbo Inlay - Stonewash M390 - Serial 104

Orca 2.0 Frame Lock Flipper with Green TechnoCarbo Inlay - Stonewash M390 - Serial 120

Orca 2.0 Frame Lock Flipper with Orange Dark Matter FatCarbon Inlay - Stonewash M390 - Serial 133

Orca 2.0 Frame Lock Flipper with African Wild Olive Inlay - Stonewash M390 - Serial 137

Orca 2.0 Frame Lock Flipper with Orange TechnoCarbo Inlay - Stonewash M390 - Serial 097

Gatsby Steak Knife with SG2 Stainless Damascus San Mai and Cocobolo Liberty Wood (Set of 4)

Orca 2.0 Frame Lock Flipper with African Blackwood Inlay - Stonewash M390 - Serial 173

Orca 2.0 Frame Lock Flipper with African Blackwood Inlay - Stonewash M390 - Serial 170

Orca 2.0 Frame Lock Flipper with African Blackwood Inlay - Stonewash M390 - Serial 159

Orca 2.0 Frame Lock Flipper with Blue TechnoCarbo Inlay - Stonewash M390 - Serial 204

Orca 2.0 Frame Lock Flipper with Blue TechnoCarbo Inlay - Stonewash M390 - Serial 190

Orca 2.0 Frame Lock Flipper with Green Mammoth Molar Inlay - Stonewash M390 - Serial 203

Orca 2.0 Frame Lock Flipper with Green Mammoth Molar Inlay - Stonewash M390 - Serial 201

Orca 2.0 Frame Lock Flipper with Green Mammoth Molar Inlay - Stonewash M390 - Serial 163

Orca 2.0 Frame Lock Flipper with Dyed Warthog Tusk Inlay - Stonewash M390 - Serial 187

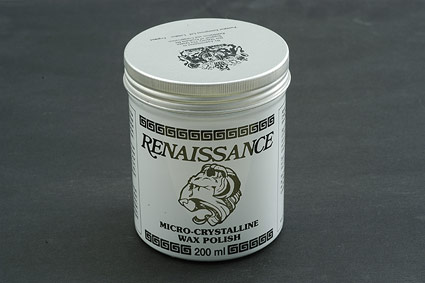

Renaissance Wax (200ml)

Renaissance Wax is the #1 choice of major museums and art galleries for the preservation of the precious pieces.

Renaissance Wax is a revolutionary formula that is a semi-synthetic micro-crystalline fossil-origin wax entirely free of, damaging acids. It remains chemically neutral and is therefore completely safe, even on vulnerable surfaces.

Guard your precious pieces against the damaging effects of humidity, heat, dust, environmental destruction, aging, and ordinary wear. Renaissance Wax provides a barrier against fingerprints and the devastation of water, wine, alcohol and other spills. With its high moisture resistance, it forms a durable, lustrous protective coating. Prevents tarnish, corrosion and "bloom". Remains completely waterproof.

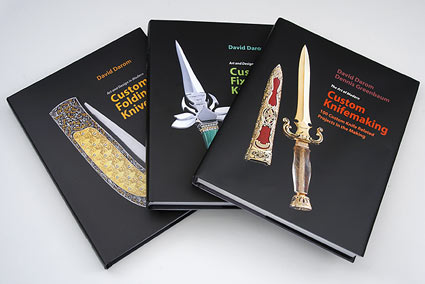

Three Books by Dr. David Darom: Art and Design in Modern Custom Fixed-Blade Knives, Art and Design in Modern Custom Folding Knives, and The Art of Custom Knifemaking

Special Price!! Both of Dr. David Darom's books sold together! Full retail price of both books: $255 (33% discount)

Art and Design in Modern Custom Folding Knives

Art and Design in Modern Custom Fixed-Blade Knives

The Art of Custom Knifemaking: 100 Custom Knife Related Projects in the Making

These books are unique among books about custom knives. They provide unparalleled photography and information about some of the best knife makers in the world.

These books provides insight into the personal lives of the artists as well as their thoughts and feelings about their craft -- breathing life into steel objects. This was achieved only by the full and enthusiastic cooperation of everyone involved, presented here in the form of their biographies and signed personal statements.

To complete the documentation of this astounding modern art form, a group of world experts wrote an original introduction to the books.

Flitz Metal Polish (150g)

Flitz is an excellent metal polish for carbon steel knives as well as fiberglass. This anti-tarnish formula lasts up to 6 months. It is non-abrasive, non-toxic, non-flammable, acid-free, won't dry out, and leaves behind no residue. Not designed for Damascus steel.

$22.95 DetailsJapanese Straight Razor (Wa-kamisori)

Shaving can be a drudgery or an indulgence. For the best shaving experience, you should consider trying a Kamisori, the traditional Japanese straight razor. After your first use, you will never forget it! Although the close shave of this straight razor is unparalleled, it does take some time and practice to achieve perfection. Although it may be difficult at first, with practice and patience, the Japanese straight razor is easy to master.

The long history of Japanese straight razors can be traced back over 1,400 years. The razor was originally used to shave monks' heads during rituals. In the Middle Ages, they were used to shave the heads of warriors.

Although Japanese razors are sharpened on both sides like Western razors, they are not symmetrical. One side is flat-concave and called "Ura" and the other is oblique-concave and called "Omote".

This Wa-kamisori, Japanese straight razor, is a perfect example of the Japanese aesthetic. This razor was produced in the workshop of bladesmith Shigeyoshi Iwasaki (b. 1933), in cooperation with his apprentice Ryoichi Mizuochi. Shigeyoshi-san is the son of renowned metallurgist and sword researcher, Hiroshi Iwasaki, who is well respected as a leading authority on traditional forging techniques. Shigeyoshi Iwasaki is considered by many to be the greatest straight razor maker of all time. His work is quite simply beyond compare.

Made of the finest carbon steel and fire-forged with Rentetsu iron (wrought iron), the blade is polished with natural sharpening stones. The blade bear's Iwasake's mark on the back of the blade.

These razors are a source of great pleasure for collectors and users alike. Delivered in a beautiful kiri-wood case.

Rust Eraser (Sabitoru), Fine (320 grit)

This Rust Eraser nicely cleans and buffs away scratches & light surface rust on metal surfaces and more. 320 grit abrasive is suspended in a slightly "springy" rubber matrix, making it perfect for cleaning up slight imperfections on both curved and flat surfaces. The 320 grit Rust Eraser is very quick to remove rust and scratches and provides a clean looking satin finish. To clean up a surface faster, either start at the 46 grit Rust Eraser or the 120 grit Rust Eraser.. Measures approx. 2 3/4 inches x 1 1/2 inches x 1/3 inch.

Made in Japan.

Camellia Oil, 60ml (2 oz)

For centuries, camellia oil has been used to protect the finest Samurai swords. A small amount applied to your carbon steel knives will keep them free of corrosion and rust. Camellia oil is non-toxic and non-allergenic.

This spray bottle is a great size for professional chefs who want a bottle to carry in the knife bag.

Chef Steps Ceramic Rod and Cleaner

This set has everything you need to properly take care of your knives.

Ceramic rods provide the best touch up possible between sharpening. By removing very little material, the blade is honed to a razor edge. Fine ceramic rods will hone a knife to the most optimal edge. However, if a considerable time has passed since honing or sharpening, a coarse rod is often required. Generally, a ceramic rod should be approximately the length of the longest knife that you will be honing. This set comes with a 12 inch fine ceramic rod.

Over time, ceramic rods build up metal particles that clog the abrasive surface. The Superaser cleans the surface of all ceramic rods so that they will continue to hone just like they did when they were new.

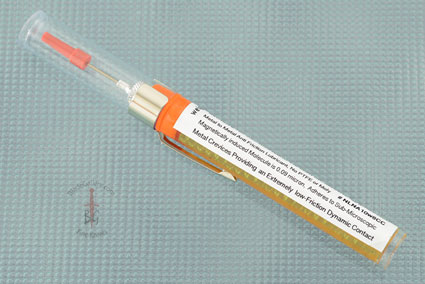

Nano-Oil (10W8CC)

Nano Oil is our favorite lubricant for folder mechanisms. The 10 weight oil ensures smooth action instantly.

At under .090 micron in size, the active molecules of Nano-Oil are called Nano Bearings. They truly are within the nano scale technology. They are magnetically induced to adhere to microscopic crevices and actually penetrate metals, providing a very low friction, dynamic contact.

NanoLube formulations are compatible with most existing lubricants on the market today - both synthetic & mineral. The Nano-Bearings concentration level is such that adding a few drops to a common lubricant will dramatically improve its anti friction qualities.

The convenient needle applicator makes is easy to apply oil exactly where it is needed!

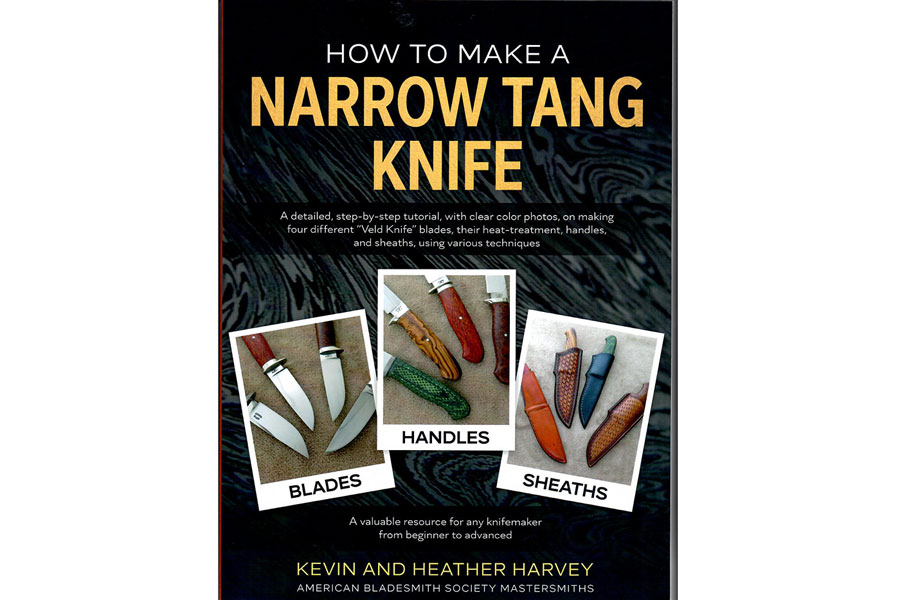

How To Make A Narrow Tang Knife

Beginning with making, heat treating, and sharpening a stock removal knife and moving into forging, forming the handle, and sewing the sheath, this exceptional manual is sure to help avoid many of the pitfalls that many knifemakers encounter as they begin their path. Even experienced knifemakers are sure to find different techniques that will improve their process and provide new approaches. How to Make a Narrow Tang Knife is sure to become a daily companion.

This book is signed by Kevin and Heather Harvey.

Mastersmiths Kevin and Heather Harvey have had a tremendous influence of forged South African custom knives. When I first met them in 1998 at the ABS Bladesmithing School in Old Washington, AR, it was clear that they arrived with exceptional talent and drive. What wasn't yet apparent was the number of bladesmiths that they would educate and inspire over the years to come. Rather than just returning to South Africa after our courses at the ABS school and proceeding to make their knives, they were immediately inspired to share the knowledge they gained.

They soon founded Heavin Forge and have taught countless bladesmiths from all over the world their techniques for knifemaking. Their style and methods are found in nearly every bladesmith coming out of South Africa today. Their devotion to sharing their knowledge has created a boon for knifemakers in and around Southern Africa.

When COVID19 began to spread in the spring of 2019, Heavin Forge needed to pivot. Their intimate classes would not be viable for several years to come. During this time, rather than simply ruminating, Kevin and Heather worked together to write and create this how-to manual. The photos and exceptionally detailed descriptions walk the reader through every step of making a knife. Having instructed thousands of students over 25 years at Heavin Forge and teaching at the ABS School, Mastersmiths Kevin and Heather understand the problems that beginning bladesmiths will encounter. This manual nicely catches those mistakes and explains each step in an easy-to-follow format.

- Publisher: Heavin Forge Media (July 13, 2022)

- Language: English

- Paperback: 272 pages

- ISBN-10: 0639714382

- ISBN-13: 978-0639714387

- Dimensions: 8.5 x 0.71 x 11 inches

Of Knives And Men - Great Knifecrafters Of The World And Their Works by Francois-Xavier Salle

Of Knives and Men is a superb display of the world's foremost contemporary knifecrafters.

The 46 artisans and their works selected for this book are the most representative of the last 30 years. Each has their own style and character, mixed with utility and the knifemaking tradition of their home country and culture. Others are quite startling in their inventiveness: a simple steel knife with a handle made from a fox's lower jaw (Mickaël Moing, France); damascus steel blade and an ancient mammoth ivory handle (Pekka Tuominen, Finland); stainless steel blade with an ironwood handle encrusted with mother of pearl and precious stones (Harumi Hirayama, Japan); and a "button lock" knife of damascus steel, with a handle of damascus, gold, titanium and mother of pearl (Michael Walker, USA).

The knifemakers are from many countries -- Brazil, USA, France, Slovakia, Finland, Japan, Italy, Canada, South Africa and more -- displaying a stunning variety of materials and techniques.

There are 217 astounding knives and sheaths in all, plus a directory of decorative materials used for the handles and sheaths -- from birds eye maple to mammoth molar, carbon fiber and fossilized coral -- and techniques from ancient and lost-and-then-rediscovered to space age. All have a grade of cost and contact information for the makers. Extra sections on embellishments like scrimshaw, engraving and sculpting of handle material are added.

This is a unique and beautiful volume that will have very wide appeal.

- Publisher: Firefly Books (September 30, 2022)

- Language: English

- Hardcover: 240 pages

- ISBN-10: 0228104009

- ISBN-13: 978-0228104001

- Dimensions: 8.25 x 0.56 x 11 inches

Orca 2.0 Frame Lock Flipper with Kudu Horn Inlay - Stonewash M390 - Serial 036

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is 036.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features a stabilized kudu horn inlay. The stabilized inlay is formed from the interior of the kudu horn and combines chocolate and cream tones. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with African Blackwood Inlay - Stonewash M390 - Serial 108

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #108.

The blade is hard ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features African blackwood (Dalbergia melanoxylon) inlay. The near-black wood has slight chocolate striations for a dramatic appearance. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

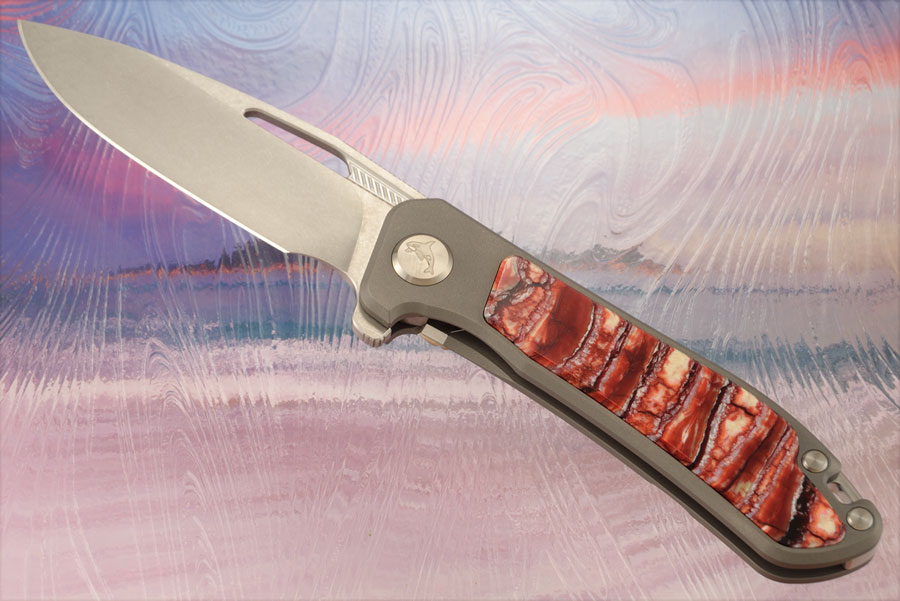

Orca 2.0 Frame Lock Flipper with Red Mammoth Molar Inlay - Stonewash M390 - Serial 088

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is 088.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features red woolly mammoth molar inlay. The ancient tooth has a a nice mix of red and white tones. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Spalted Beech Inlay - Stonewash M390 - Serial 080

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #80.

The blade is hard ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features stabilized spalted beechwood inlays. The dramatic wood has a nice mix of mid and darker tones with black spalting lines moving through the figure. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Gold Snakeskin FatCarbon Inlay - Stonewash M390 - Serial 129

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is 129.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features a Gold Snakeskin FatCarbon inlay. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Green TechnoCarbo Inlay - Stonewash M390 - Serial 104

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #104.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features a green TechnoCarbo inlay. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Green TechnoCarbo Inlay - Stonewash M390 - Serial 120

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is 120.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features a green TechnoCarbo inlay. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Orange Dark Matter FatCarbon Inlay - Stonewash M390 - Serial 133

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #133.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features Orange Dark Matter FatCarbon inlay. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with African Wild Olive Inlay - Stonewash M390 - Serial 137

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #137.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features African wild olive wood inlay. African wild olive(Olea europeae sub sp. Africana) is a South African hardwood. It is a hard, dense timber and is tremendously resilient -- exactly what we would hope for in a knife handle. The buttery yellow wood has a nice mix of light and dark tones. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Mopane Inlay - Stonewash M390 - Serial 135

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #135.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features a mopane wood inlay. Mopane(Colophospermum mopane) is a South African hardwood. It has a warm hue and mixes darker and light tones. Its high density and durability are virtually unrivaled. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Mopane Inlay - Stonewash M390 - Serial 158

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #158.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features a mopane wood inlay. Mopane(Colophospermum mopane) is a South African hardwood. It has a warm hue and mixes darker and light tones. Its high density and durability are virtually unrivaled. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Orange TechnoCarbo Inlay - Stonewash M390 - Serial 097

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is 097.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features orange TechnoCarbo inlay. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Gatsby Steak Knife with SG2 Stainless Damascus San Mai and Cocobolo Liberty Wood (Set of 4)

Bradford Knives are handmade in Renton, Washington. His background working in an aerospace machine shop is clearly evident in these high performance, elegant steak knives.

We're very excited about these steak knives. In fact, they are literally some of the best steak knives we've ever seen!.

Super Gold II (SG2) powdered metallurgical (PM) steel is combined with the beauty of damascus cladding. A high performing Takefu SG2 PM stainless steel core is surrounded by thin layers of stainless damascus steel. The resulting cutting edge is tempered to Rc 62 - 63 (very hard!) for exceptional edge holding, but is easy to sharpen due to the small grain structure. The incredibly small crystalline size of this PM steel results in superior edge holding when compared to nearly any other stainless steel used in the knife industry.

The blades are full flat ground for high performance, effortless slicing. They were heat treated by Peters' Heat Treating, for a superior, long lasting edge (Hrc 62-63).

Cocobolo toned Liberty Wood handle scales are set on the full tang using Corby fasteners. Liberty Wood is a natural, engineered wood laminate using sustainably-sourced birch veneer and resin. The water-based resin is infused deep into the wood fibers which acts as a plasticizer and gives the final material its characteristics. Its durability greatly exceeds that of normal hard woods and it is able to obtain a high polish. The handles are nicely contoured with a palm swell.

This four knife set is accompanied by a leather storage pouch, also made in the USA.

Exceptional fit and finish!

Orca 2.0 Frame Lock Flipper with African Blackwood Inlay - Stonewash M390 - Serial 173

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #173.

The blade is hard ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features African blackwood (Dalbergia melanoxylon) inlay. The near-black wood has slight chocolate striations for a dramatic appearance. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with African Blackwood Inlay - Stonewash M390 - Serial 170

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #170.

The blade is hard ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features African blackwood (Dalbergia melanoxylon) inlay. The near-black wood has slight chocolate striations for a dramatic appearance. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with African Blackwood Inlay - Stonewash M390 - Serial 159

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #159.

The blade is hard ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features African blackwood (Dalbergia melanoxylon) inlay. The near-black wood has slight chocolate striations for a dramatic appearance. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Blue TechnoCarbo Inlay - Stonewash M390 - Serial 204

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #204.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features blue TechnoCarbo inlay. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Blue TechnoCarbo Inlay - Stonewash M390 - Serial 190

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #190.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features blue TechnoCarbo inlay. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Green Mammoth Molar Inlay - Stonewash M390 - Serial 203

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #203.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features green woolly mammoth molar inlay. The ancient tooth has a nice mix of green and white tones. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Green Mammoth Molar Inlay - Stonewash M390 - Serial 201

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #201.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features green woolly mammoth molar inlay. The ancient tooth has a nice mix of green and white tones. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Green Mammoth Molar Inlay - Stonewash M390 - Serial 163

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #163.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features green woolly mammoth molar inlay. The ancient tooth has a a nice mix of green and white tones. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Blue Kudu Horn Inlay - Stonewash M390 - Serial 198

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.

Arno Bernard's Orca 2.0 Frame Lock Flipper is an EDC designed for high performance, hard use. It is a collaboration between Arno Bernard Sr. and his sons. This redesigned flipper is truly exceptional. Each of the Orca 2.0 are individually serialized. This is flipper is #198.

The blade is hand ground, premium M390 stainless steel, tempered to Hrc 63. M390 is a super-steel created by Bohler in Austria. It takes an incredibly sharp edge and holds onto it due to a high concentration of vanadium and chromium carbides. Its unique powder metallurgical process also promotes a uniform carbide distribution and clean steel properties, making M390 a popular steel used in surgical cutting instruments and in applications requiring a high finish. It offers excellent corrosion resistance due to its high concentration of chromium. The blade is hollow ground for an easy to maintain edge. Thumb ridges on the spine ensure a secure, comfortable grip.

The blade effortlessly rotates on a Skiff-made caged ceramic ball bearings. If Skiff-made ceramic caged bearings weren’t enough, a house-made .020” tungsten disc is inserted into the titanium frame, ensuring a perfect racetrack for the bearings. The pivot barrel is 431 stainless steel, heat treated to 48 Hrc. The pivot is engraved with a detailed orca. The blade can easily be opened single handed using either the flipper tab or extended thumb notch. The blade has silky-smooth, drop-shut action, and is perfectly centered. Perfect lockup is ensured with a replaceable internal lock face. The lock face is hardened 17-4 PH stainless steel.

A glass bead blasted grade 5 titanium frame ensures this mid-size folder will be light in the pocket, yet have tremendous strength and durability. Each side features a stabilized and dyed kudu horn inlay. The stabilized inlay is formed from the interior of the kudu horn and combines blue and cream tones. Screws throughout were made in the Arno Bernard workshop and are grade 4 titanium, allowing them to be anodized. Ensuring rigid, yet light construction, the backspacer is grade 5 titanium.

It will be easy to keep the Orca 2.0 Flipper close at hand using the grade 5 titanium pocket clip, mounted for tip-up, right-side carry. The Orca 2.0 Flipper is accompanied by a handmade leather pouch for safe storage or carry. The leather pouch uses a quality YKK zipper.

Though this folder would feel at home in any collection, its thin, light design will also make it a perfect every day carry. This knife is precision-made and rock solid in every way. From the fit, finish, and execution of this knife you can’t go wrong!

The knife pictured is the actual knife you will receive.

Orca 2.0 Frame Lock Flipper with Dyed Warthog Tusk Inlay - Stonewash M390 - Serial 187

Knives by Arno Bernard Sr. are absolutely phenomenal! Arno has been making knives for over 35 years. He has been a member of the Knifemakers Guild of Southern Africa (KGSA) for over 20 years. Living in South Africa has allowed him the luxury of using many different exotic handle materials -- some even collected himself.